Thought You Couldn’t Recycle Polystyrene? Think Again.

All too often, we hear the myth that recycling polystyrene is impossible, expensive, or somehow inaccessible, especially in South Africa. In 2023, eWASA set out to prove this misconception wrong. The year’s results are in, and it turns out polystyrene recycling is not only possible, but highly profitable, practical, and easy to do!

A Record-Breaking Polystyrene Recycling Rate

In 2023, eWASA exceeded the government’s suggested recycling targets for polystyrene by over 375 tonnes! Considering the fact that it’s such a lightweight material, this achievement is no small feat.

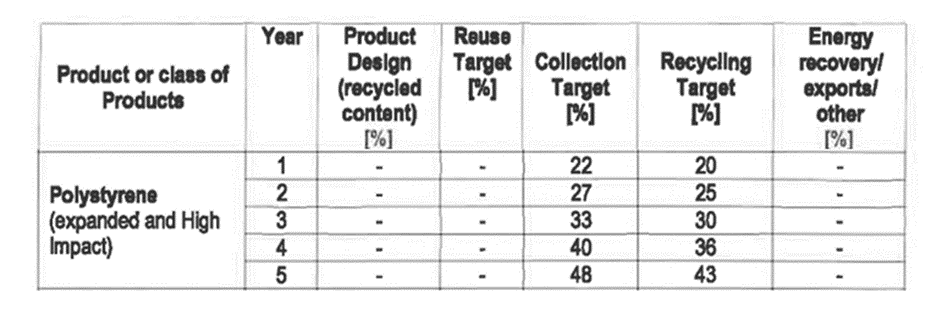

The Department of Forestry, Fisheries and the Environment published recycling guidelines for polystyrene producers under the NEM:WA Act in 2021. These guidelines include yearly collection and recycling targets for anyone who puts polystyrene products on the market. That includes all packaging companies, whether they’re importers or local manufacturers.

Here’s what the official recycling guidelines look like for the first five years:

Last year, eWASA collected and recycled 2060 tonnes of polystyrene – a whopping 31% of all the polystyrene products our producer members put on market! 2023 was our second collection year, so we hit the 25% target and passed with flying colours!

Polystyrene can officially be classified as recyclable in SA after reaching a 31% recycling rate, which allows it to carry the recyclable logo.

How eWASA and its Members Made Recycling a Reality in 2023

eWASA is a producer responsibility organisation (PRO)–a group of businesses that recycle together to meet the EPR obligations required of them by law. Our members pay EPR fees proportional to the amount of material they manufacture or import for sale in South Africa. eWASA pools these fees to run collection and recycling schemes on our members’ behalf.

One of our biggest polystyrene recycling initiatives in 2023 was the purchase of six ingot machines that can melt used polystyrene into small, transportable bars. Expanded polystyrene (the type we use for takeaways and electronics packaging) is 96% air, so it takes up a lot more space than its weight is really worth.

By compressing it into dense, compact ingots, recyclers can store and transport polystyrene with much less hassle. They no longer have to hire massive storage yards for it or waste petrol making multiple trips to its final destination. Our ingot machines make polystyrene recycling easier, more cost-effective, and more attractive as a business.

What Happens to All That Recycled Polystyrene?

2060 tonnes is a lot of polystyrene–where does it end up after recycling? With the help of a few eco-conscious South African businesses, we helped turn our members’ used products into brand-new products for the construction and design industries.

Here are two ways we upcycled the polystyrene we collected in 2023:

- Lightweight concrete. We sent truckloads of post-consumer polystyrene to Envirolite for recycling in 2023. This eco-friendly construction company uses recycled polystyrene to make concrete bricks and slabs. These recycled products meet all South African building codes and are lightweight and easy to install.

- Cornices, skirtings, and picture frames. We partnered with South African decor company Supreme Mouldings to fuel the recycled finishes market in 2023. The company turns used polystyrene into high-quality award winning wall panelling skirting boards, ceiling cornices, picture frames, and more. These recycled products are durable, waterproof, and locally made.

Saving Our Environment and Boosting Our Economy

Why is polystyrene recycling important? The first part of the answer is because it reduces pollution levels in the natural environment. Polystyrene is light enough to float, so heavy rains can carry it from littered streets and landfills into rivers, lakes, and our oceans.

Recycling helps us recover some of the polystyrene we throw away and put it to better use.

The second reason we should be recycling polystyrene in South Africa is to boost the economy. Through our recycling efforts alone, we were able to uplift dozens of disadvantaged people through skills development and job creation.

Recycling plants need staff, managers, and skilled consultants while collection schemes need planners and marketing teams. Creating demand for recycled products helps future entrepreneurs find customers, which could eventually lead to export opportunities.

Implications for the Polystyrene Industry

eWASA’s success with polystyrene recycling sets a positive example for other recyclers and PROs. It proves that any material can be recycled with the help of willing stakeholders–businesses, waste collectors, and consumers.

In light of this understanding, people’s attitudes towards polystyrene may change for the better. Polystyrene packaging manufacturers can continue this narrative by including recycling instructions with their products, starting take-back schemes, and raising awareness in general.

Changing perceptions about the recyclability of polystyrene can lead to better opinions of the industry overall. Polystyrene manufacturers and importers now have a more sustainable end-of-life option for their products, which can help them establish themselves in the green business space.

Let’s Recycle Polystyrene Together

Does your business deal in polystyrene? We’re looking for wholesalers, retailers, and resellers to join the recycling revolution and help us smash our 2024 recycling goals. Consumers can also get involved by collecting polystyrene packaging and sending it to one of our recycling partners.

Join eWASA today or get in touch with us for more information.