Types of Lubricant Oils to Know for EPR

Lubricant oils are a mainstay of industrial work. They lubricate heavy machinery and help vehicle engines run smoothly, and without them, the economy would quite literally grind to a halt. Lubricants have been used since ancient times and we’ve been drilling for crude oil since the 1800s. Today you can find lubricant oils in cars, trucks, cranes, forklifts, buses, tractors, conveyor belts, the list goes on.

Despite their usefulness, disposing of lubricant oils incorrectly can cause pollution. That’s why the Department of Forestry, Fisheries, and the Environment (DFFE) mandated EPR legislation for lubricant oils in 2023.

Under EPR (extended producer responsibility), producers in the industry must run collection and recycling programmes for used oil. We explore the different types of lubricant oils below to make sorting and recycling easier for producers.

Understanding What Lubricant Oil is Made Of

Lubricant oil is made of two main ingredients: base oil and additives. The base oil is the main component, which typically makes up 70 – 95% of the final lubricant product. Most base oils are refined from crude oil. Refiners make base oil by processing crude oil until it meets certain standards for viscosity and volatility.

Additives are extras added to the base oil to improve the lubricant’s performance. Examples include anti-wear additives (protects metal machinery from damage under high pressure) and anti-corrosion additives.

Classification System for Lubricant Oils: Base Oil Groups

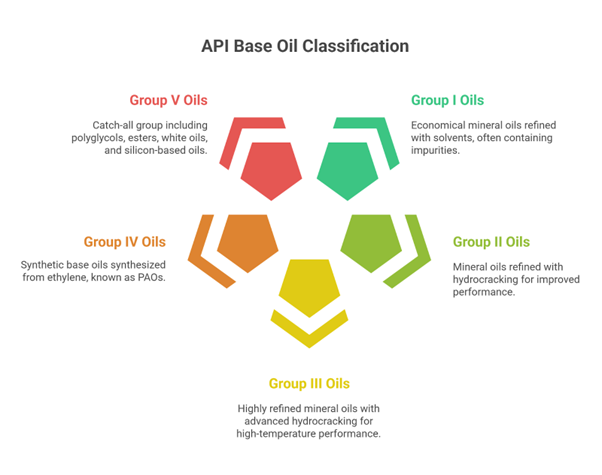

Many oil producers conform to the standards set by the American Petroleum Institute (API). There are five API base oil groups. We use these to classify base oils according to their quality.

- Group I – an economical mineral oil (made from crude oil) that has been refined with solvents. Group one oils are the least refined of all the groups and may contain impurities.

- Group II – mineral oils refined with hydrocracking to improve their performance. Group two oils are more saturated than group one oils.

- Group III – the most refined of all the mineral oil groups. Group three base oils undergo advanced hydrocracking to increase their performance under high temperatures.

- Group IV – these are synthetic base oils also known as polyalphaolefins (PAOs). Group four base oils are synthesized from ethylene.

- Group V – a catch-all group for all the other base oils that do not fit into groups one to four. Group five base oils include things like polyglycols (PAGs), esters, white oils, and silicon-based oils.

Mineral-Based Lubricant Oils vs Synthetic Lubricants

Lubricant oils marketed as “synthetic” may contain base oils from one or more of the following groups, three, four or five. Natural lubricant oils, those refined from crude oil, are mineral-based and contain base oils from groups one to three.

Synthetic lubricants are made in controlled environments and undergo significant chemical alterations to achieve specific molecular structures. They are typically higher performance oils with more tolerance to heat stress. Even though some synthetic oils start as petroleum byproducts, they are still classified as synthetic because of the sophisticated processing they have undergone.

Bio-Based Lubricant Oils

Biolubricants are made from renewable resources instead of crude oil and its byproducts. They come from plant and animal sources, and contain base oils that fall into Group five. Examples of bio-based lubricants are:

- Canola oil – used for lubricating engines and machines since the 1700s.

- Linseed oil – the base ingredient for linseed soap, a mining industry lubricant.

- Tallow – used to make industrial greases, provides heat protection for metal parts.

- Palm oil – bar and chain oils for chainsaws. Food grade lubricants.

- Castor oil – lubrication for two-stroke engines and race cars. Also works as hydraulic fluid.

Because of their renewable sources, bio-based lubricants are often considered more environmentally friendly than mineral oils. Notably, vegetable oils are not currently subject to EPR in South Africa.

Extended Producer Responsibility for Lubricant Oils

Extended producer responsibility is about disposing of lubricant oils safely to protect the environment. EPR requires that lubricant oil producers run collection and recycling schemes for used oil. Under the EPR regulations, all lubricant producers must have an EPR scheme in place.

Other obligations of lubricant oil producers under EPR:

- Run take-back schemes for used lubricant oils

- Submit information on waste generation and collection to SAWIC

- Report on EPR performance to the DFFE

- Implement cleaner production methods and green design

Remain EPR Compliant With eWASA

Not sure whether you are liable for EPR? eWASA can help. Contact us to learn more about EPR in the lubricant oils industry and find recycling solutions for your business. We are a registered producer responsibility organisation (PRO) that helps lubricant oil producers run comprehensive EPR schemes and meet environmental reporting requirements. Join our scheme today to build a greener business for the future.