Frequently Asked Questions: EPR Waste Management South Africa

Answering Your Questions About EPR, PROs, Membership, e-Waste, Lighting or Paper and Packaging Waste

We’ve compiled a list of questions and answers for those queries we often get. If you don’t see the clarification you need here, please send us an email with your query.

General FAQ's

What is e-waste?

Electronic and electrical waste includes ICT equipment, consumer electronics, small household appliances and large household appliances.

Why should we recover e-waste?

Electronic and electrical waste contains both valuable and potentially hazardous materials. Valuable fractions can be recovered through proper recycling, while hazardous fractions can be treated and made safe prior to safe disposal.

What are the possible health effects of e-waste mismanagement?

E-waste recycling has direct and indirect effects on human health conditions. Direct impacts on human health may be caused by:

- Dust in indoor air generated in manual and mechanical dismantling processes (e.g. when processing plastics or Cathode Ray Tubes (CRTs) found in old TVs and Computer screens);

- Filter dust generated in the mechanical dismantling process;

- Noise emissions during the manual and mechanical dismantling process (conveyor belts, hammering, shredders etc.);

- Deviations from occupational safety standards;

Indirect impacts on human health may be caused by:

- Air pollution related to (HT) incineration (however the situation has been very much improved since waste gas purification systems are a common standard);

- Emissions due to transportation of materials;

- Contamination of water systems and soil near landfills.

- The indirect impacts on human health are difficult to quantify, because of synergistic effects and the time lag between exposure and reaction.

What are the Section 18 EPR Regulations?

Section 18 Extended Producer Responsibility Regulations are the regulations published under Government Notice 1184 in Government Gazette 43879 on 5 November 2020 and as amended. Extended Producer Responsibility means that a Producer’s responsibility for an identified product is extended to the post-consumer stage of an identified product’s life cycle. The purpose of these Regulations is to provide the framework for the development, implementation, monitoring and evaluation of extended Producer responsibility schemes by Producers in terms of section 18 of the NEMWA act (2008); to ensure the effective and efficient management of the identified products at the end of their life and to encourage and enable the implementation of the circular economy initiatives.

Visit the Resources section of our website to view the various legislations governing waste management and EPR.

How do I know that I am liable for EPR?

Extended Producer Responsibility (EPR) is an environmental policy approach in which a Producer’s responsibility for an identified product extends to the post-consumer stage of a product’s life cycle. Thus the Producer, according to the EPR Regulations’ definition, becomes liable for their products placed on the market.

What are the steps to be considered a compliant member?

- Registered with the DFFE via the SAWIC website

- Registered as a member with eWASA (PRO)

- Provided 5-year forecasts for the identified products placed on the market

- Selected the payment frequency and pay EPR Fees/levies timeously

- Signed an SLA with eWASA for not less than 12 months

How are EPR fees calculated?

The EPR fee/levy is the price a Producer pays to the Producer Responsibility Organisation in return for carrying out the Producer’s EPR responsibilities.

According to the Regulations, the Producer responsibility organisation that establishes and implements an extended Producer responsibility scheme must, together with its members, determine the proposed extended Producer responsibility fee and apply the extended Producer fee proportionally to all members based on the identified products placed on the market.

This extended Producer responsibility fee must be based on net cost recovery, including a differentiated rate per item category of each product or class of product, which must be paid by a Producer to fund extended Producer responsibility schemes and be dependent on the following:

- weight of the product;

- ease of recyclability;

- current demand for the material for recycling purposes;

- costs for establishing a collection system for the identified products;

- collection, transport, storage and treatment costs for separately collected waste;

administrative costs - costs for public communication and awareness raising (on waste prevention, litter reduction, separate collection, etc.)

- costs for the appropriate surveillance of the system (including auditing); and

- less revenues from recycled material sales.

What are the EPR Responsibilities of PROs?

Administrative Responsibilities

- Collect EPR Fees.

- Ensure that the EPR Scheme is audited.

- Collect and submit data related to the scheme to the South African Waste Information System (SAWIS).

- Keep a record of identified products – placed on the market, collected & sorted, recycled etc.

- Compensate informal waste collectors.

Facilitating/Enabling Responsibilities

- Contract for the collection, recycling and recovery of identified products.

- Cooperate with municipalities to increase the collection of identified products.

- Integrate informal waste collectors.

- Establish secondary markets for recycled content.

- Utilise new and existing infrastructure or establish new infrastructure.

What can be recycled?

In South Africa, you can recycle paper, cardboard, liquid cartons (TetraPak), PET plastic bottles, polystyrene, plastic bags, hard plastics (HDPE and PVC), bread tags, glass, scrap metal, e-waste, batteries, lightbulbs, and motor oil. This is not an exhaustive list as new recycling technologies are always emerging.

Things you can NOT recycle right now are: tissues and tissue paper, cling wrap, nappies, wet paper/cardboard, dirty food takeaway containers.

Why Should I Join eWASA as a Producer?

When joining eWASA, you will have the advantage of complying with all your EPR obligations as a Producer and benefit from the following:

- Certification with a DFFE-approved PRO

- Quality services from collection points for your customers

- Transparent reporting on financial and operational data

- Regular legislative updates, guidance, and seminars

- Compliance support and training for your organisation on request

- Permission to use the eWASA logo on your stationery and website

- Options to collaborate on projects with eWASA

- One Stop Shop with Access to a team of experts and dedicated Key Account Managers per Waste Stream

- Receipt of a Compliance certificate which you can upload on your website

- Regular working groups on-the-ground, co-creation of tailored initiatives that are best suited to each member in achieving their sustainability objectives.

And much more!

View our full member benefits here.

Why Should I Join eWASA as a Recycler?

Become a member and benefit from:

- Certification with a DFFE-approved PRO

- Access to a wide range of EPR waste streams, including EEE, Lighting, and Paper and Packaging

- Quality service collection points for your customers

- Transparent reporting on financial and operational data

- Opportunities for skills training within the industry

- A complimentary subscription to our official newsletter

- Access to legislation policies and updates in the member section of our website

- Permission to use the eWASA logo on your stationery and website

- Options to collaborate on projects with eWASA

- A location marker on our website map – www.ewasa.org

- Rebates when you provide us with compliant reports to collections done at our Producer members.

And much more!

View our full member benefits here.

Is eWASA registered?

eWASA is a registered Producer Responsibility Organisation (PRO) in the following sectors:

- Electrical and Electronic Equipment: 19/7/6/E/PRO/20210512/001

- Lighting 19/7/7/L/PRO/20211123/004

- Paper and Packaging: 19/7/5/P/PRO/20211123/022

- Portable Batteries: 19/7/5/P/PRO/20230710/045

- Lubricant Oils: 19/7/7/L/PRO/20240429/053

Paper & Packaging FAQ's

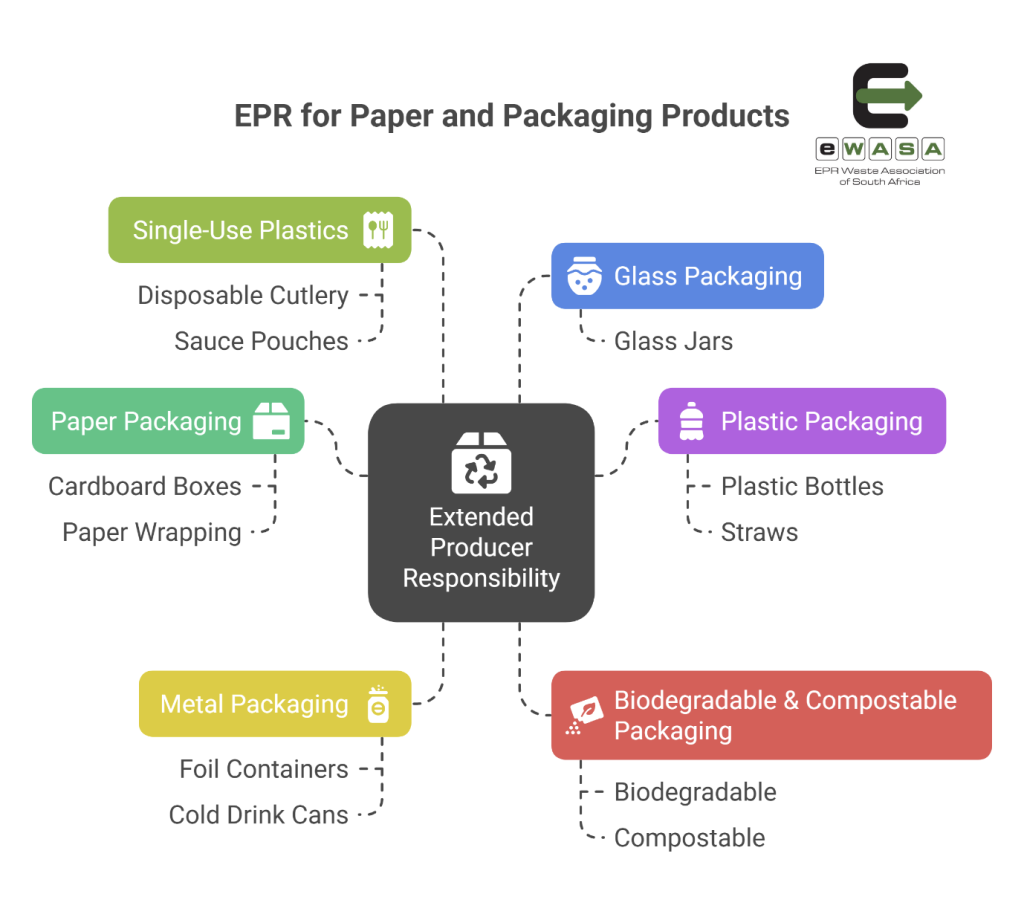

What's included in the Paper and Packaging Products EPR?

Extended producer responsibility (EPR) regulations for paper and packaging includes the following products:

Examples of packaging that are subject to EPR are cardboard boxes, paper wrapping, void fills, plastic bottles, glass jars, foil containers, cold drink cans, food tins, egg containers, straws, sauce pouches, and disposable cutlery.

What can be recycled?

In South Africa, you can recycle paper, cardboard, liquid cartons (TetraPak), PET plastic bottles, polystyrene, plastic bags, hard plastics (HDPE and PVC), bread tags, glass, scrap metal, e-waste, batteries, lightbulbs, and motor oil. This is not an exhaustive list as new recycling technologies are always emerging.

Things you can NOT recycle right now are: tissues and tissue paper, cling wrap, nappies, wet paper/cardboard, dirty food takeaway containers.

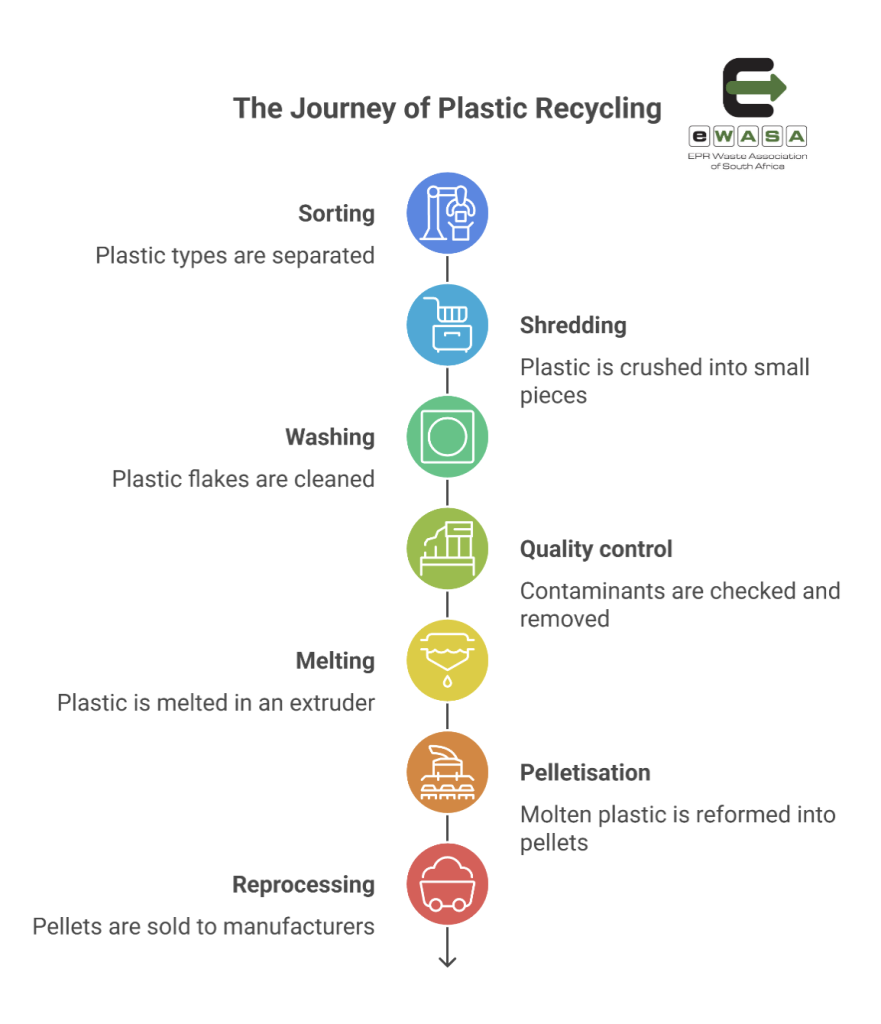

What is the recycling process for plastics?

- Sorting – plastic types are separated (PET, PVC, etc) – this can be done manually or using robotic optical scanners. Any non-plastic materials are removed.

- Shredding – plastic goes through a grinder that crushes it into small pieces. The final product is called plastic flake.

- Washing – the plastic flake is cleaned to remove adhesives and dirt. It can now be sold as-is or further processed to make other raw materials.

- Quality control – plastic flakes are sorted again to check for contaminants. Float tanks help separate lighter plastics from heavier plastics. Once sorted, it is rinsed and dried.

- Melting – the checked plastic is melted in an extruder.

- Pelletisation – the molten plastic is reformed into small pellets called nurdles.

- Reprocessing – nurdles are sold to manufacturers that can use them to make new products.

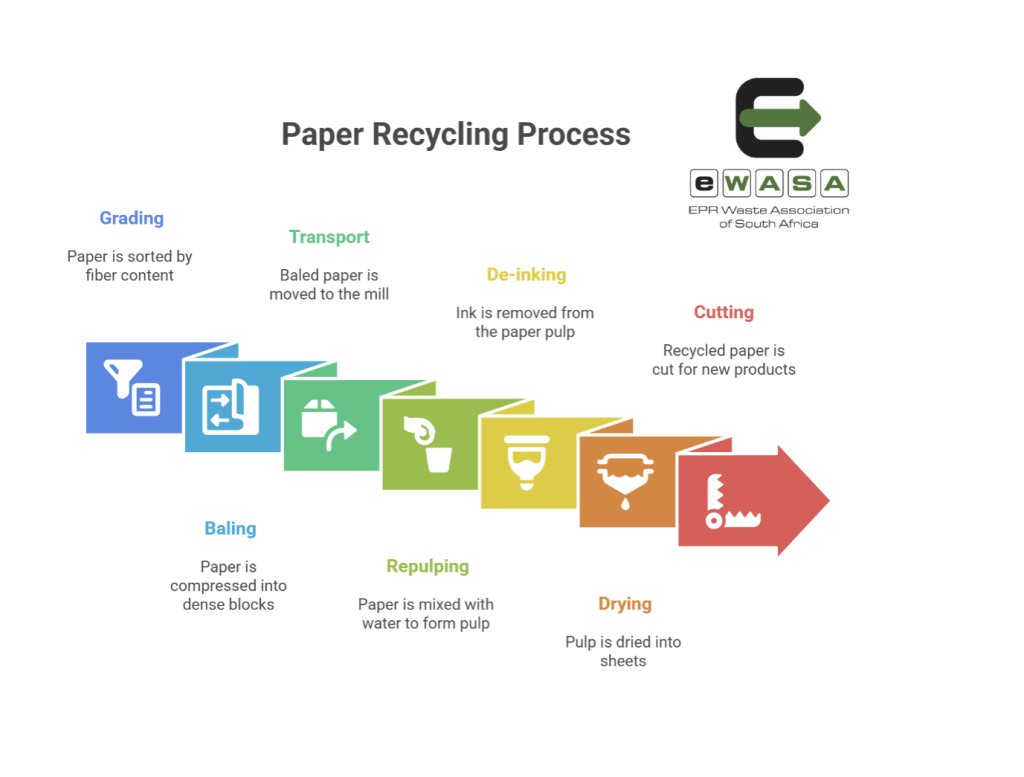

What is the recycling process for paper?

- Grading – paper is sorted into grades according to its fibre content.

- Baling – the sorted paper is compressed into dense blocks using a paper baler.

- Transport – baled paper goes to the paper mill.

- Repulping – paper is mixed with water and broken down into a fibrous pulp.

- De-inking – ink is removed/cleaned out of the paper pulp. It may also be bleached.

- Drying – pulp is laid out in sheets and dried using heat and air.

- Cutting – the recycled paper is ready to be made into new products.

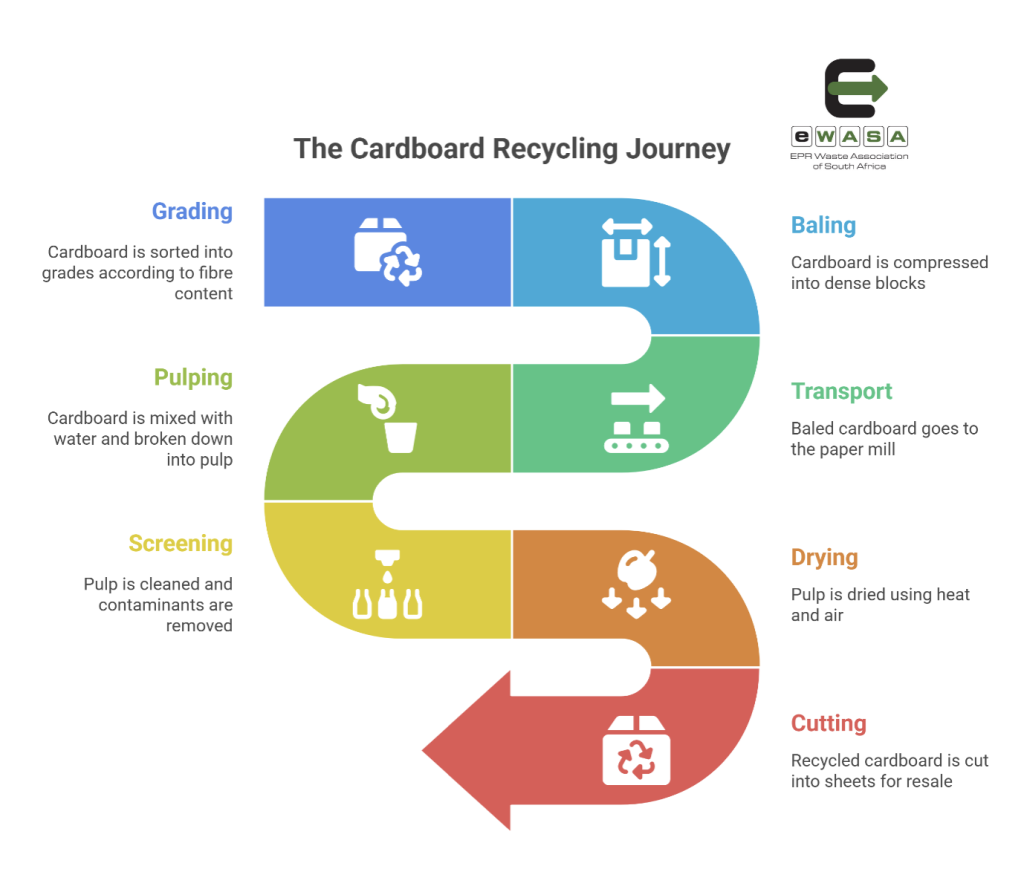

What is the recycling process for cardboard?

- Grading – cardboard is sorted into grades according to its fibre content.

- Baling – the sorted cardboard is compressed into dense blocks using a baler.

- Transport – baled cardboard goes to the paper mill.

- Pulping – cardboard is mixed with water and broken down into a fibrous pulp.

- Screening – the pulp is cleaned and contaminants (glue, staples, tape) are removed.

- Drying – the pulp is dried using heat and air.

- Cutting – the recycled cardboard is cut into sheets ready for resale.

Lighting FAQ's

What type of waste is a light bulb?

A light bulb is considered a type of lighting waste, and its specific classification depends on the kind of bulb: many are regulated as hazardous waste due to their chemical content, while some can be disposed of as general waste under strict guidelines.

Types of Light Bulbs and Waste Category

- Compact Fluorescent Lamps (CFLs) & Fluorescent Tubes: These bulbs contain hazardous substances such as mercury and are classified as hazardous waste. They must be disposed of at qualified recycling centres and should not be placed in regular household waste.

- LED Bulbs: LEDs may contain heavy metals like lead, nickel, and copper. While they are considered less hazardous than mercury-containing bulbs, they still require proper recycling and must not be sent to landfills.

- Incandescent and Halogen Bulbs: These do not contain mercury and are not classified as hazardous waste. Disposal may be allowed with household trash, but recycling is recommended where possible due to the presence of metals and glass.

- Other lamp types (e.g., neon, HID): May contain high concentrations of hazardous substances, such as mercury or lead, and are typically classified as hazardous waste.

Regulations and Environmental Impact

- South Africa and many countries have banned disposable electrical lamps from landfills and require all hazardous lighting waste to be recycled or processed through formal channels due to risks to soil, air, and groundwater. Lighting manufacturers are obliged under Extended Producer Responsibility (EPR) schemes to offer take-back, recycling, and proper disposal solutions for end-of-life bulbs.

Can I put light bulbs in my recycling bin? Can a light bulb be recycled?

Hazardous bulbs (CFLs, fluorescent tubes, some LEDs, neon, HID): Must be taken to collection points or recycling centres. Take care not to break the glass when you put it in the recycling. Placing the broken lamp in the box of your replacement bulb is a good way to protect the glass.

Is a light bulb e-waste?

In South Africa, EPR regulations cover lighting products separately from e-waste, but lamps are still considered e-waste under the waste classification system.

Can I put old light bulbs in the bin?

No, it should be taken to a specialised recycler that can handle lamp waste. LEDs, CFLs and HID, and neon lamps contain hazardous materials.

How do you safely/correctly dispose of light bulbs?

Selected retailers have bins for lamps and batteries where you can safely drop off your broken light bulbs.